About the application of MIM metal injection molding technology

Harber specializes in the development and production of precision hardware fittings, all kinds of high-precision complex mechanical parts, metal-ceramic shaped structural parts, all kinds of gears, gearboxes, worm gears and the development of intelligent high-tech products. The company attaches importance to the investment in technology and process, through independent innovation, synchronous development with customers and other ways in the product structure and process flow and other aspects of the formation of a strong advantage. Our products are widely used in intelligent robots, intelligent electronic locks, intelligent time and attendance machines, intelligent home systems, intelligent sweepers, power tools, meat grinders, remote-controlled fuel cars, underwater yachts, automobile center locks, eyeglasses, cell phones, shredders, instruments, beauty equipment, medical equipment, aviation models, watches, ATM machines and so on.

Metal Injection Molding (MIM) is a near-net-shape molding process suitable for the production of small, three-dimensional and complex shapes as well as products with special performance requirements. MIM can be used with almost all metal materials, and the main application materials, taking into account the economy, include iron-based, nickel-base, low alloy, copper-base, high-speed steel, stainless steel, valves, carbide, titanium base metal, and so on. alloys, cemented carbides, and titanium-based metals.

From the economic point of view, the weight of MIM products is usually about 0.1-200 G, which can produce various complex shapes like plastic products, such as external groove, external thread, conical outer surface, cross through hole, blind hole, concave platform, key pin, reinforcing rib plate, surface knurling, etc. The products have good surface finish and high dimensional accuracy. Of course, the biggest feature of MIM should be its high production efficiency, which can realize automation, mass production and large-scale production, and can produce a large number of products in a short period of time.

Figure 1: MIM Basic Process Flow Diagram

The application of MIM is very extensive, and the MIM products that permeate our lives are mainly in the three major areas of electronic products, automobile manufacturing and medical equipment.

1. 3C Consumer Electronics

When it comes to consumer electronics, mobile phones should be the most familiar products. In addition, smart wearable devices are also a very popular application area. Mobile phone parts are relatively complex in shape, and they also pay great attention to the feel of use. As the function of the fuselage continues to climb, the parts should be more refined and the performance should meet the requirements.

Figure 2: Phone card holder -- a very classic MIM product

Electronic communication products are an important market for MIM components. Almost all mobile phone manufacturers will purchase a large number of MIM products, and the miniature and multi-functional components in communication are suitable for the advantages of MIM technology. MIM injection molding can achieve the advantages of reducing production costs, improving production efficiency, and making parts smaller and lighter. It is the advantage of mobile phone developers to achieve thin and light parts, reduce weight and improve hand feeling. The development of mobile phone projects is very fast, and only MIM technology can make so many parts in a short time.

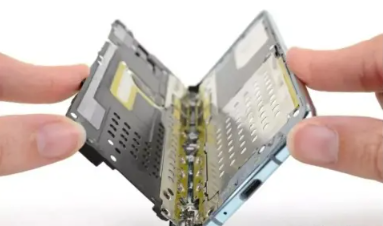

In addition to the card holder, the hinge used in the current popular folding screen mobile phone is also a MIM part. Of course, in addition to the above examples, there are many applications of MIM parts in consumer electronics.

Chart 3: The folding screen hinge requires very high precision in production, and the production is also very difficult, probably only MIM can do it.

Diagram: 4: MIM Injection Molded Communication Parts

2. Automotive field

The automotive industry is the largest user of MIM injection molded parts, accounting for about 60% of the MIM industry. Uch as complex shaped parts used in engines, gearboxes, turbochargers, synchronizer rings, lock-up mechanisms, shock absorbers, steering systems, and automotive electronic systems.

Figure 5: MIM Injection Molded Automotive Parts

Figure 6: Common MIM Injection Molded Automotive Parts

The rocker arm of the engine | The rocker arm, usually made of low-alloy steel, used to control the variable valve timing stroke of the engine, is characterized by its light weight. |

Shift lever | This is a very large amount of MIM parts, automotive manual transmission, the production process of this part: injection molding, sintering, hardening treatment and assembly shaft, after sintering, carburizing and quenching treatment. |

Shock absorber parts | The parts of shock absorber include piston, compression valve seat and connecting rod guide seat, which have complex shapes, many small holes and high dimensional accuracy. MIM injection molding can be integrally formed at one time, which reduces production costs and improves production efficiency. |

Synchronizer ring | An important component in the gearbox, if the synchronizer fails, the car can not shift gears. Most of the traditional production uses brass precision forging, which requires heating, blank making, pre-forming, final forging, trimming, finishing and other processes. Because of the high price of raw materials and process costs, many manufacturers use powder injection molding at present. |

3. Medical field

MIM injection molding is also widely used in the medical field. MIM materials used in the medical field are required to be relatively high, and the unit price of a single MIM injection molding part is much more expensive than that of an industrial MIM part.

Figure 7: MIM Injection Molded Medical Parts

Figure 8: MIM Common Materials and Their Application Fields

Material system | Alloy grade and composition | Field of application |

Low alloy steel | Fe-2Ni, Fe-8Ni | Various structural parts in automobile, machinery and other industries |

Stainless steel | 316L ,17-4PH, 420, 440C | Medical equipment, watch parts |

Cemented carbide | WC-Co | All kinds of cutting tools, clocks and watches |

Ceramics | Al2O3, ZrO2, SiO2 (of course, it may be more appropriate to call CIM ~ ~) | IT electronics, daily necessities, clocks and watches |

Heavy alloy | W-Ni-Fe, W-Ni-Cu, W-Cu | Military industry, communications, daily necessities |

Titanium alloy | Ti,Ti-6Al-4V | Medical and military structural parts |

Magnetic material | Fe, NdFeB, SmCo5,Fe-Si | Various magnetic performance components |

Tool steel | CrMo4,M2 | Various tools |