Contact Us

+86 13480709275

Block 11,Shunchang Industrial Park, Xiaobian Second Industrial Zone, Chang'an Town, Dongguan City, China

How Can We Help?

If You Need Any Helps Please Feel Free To

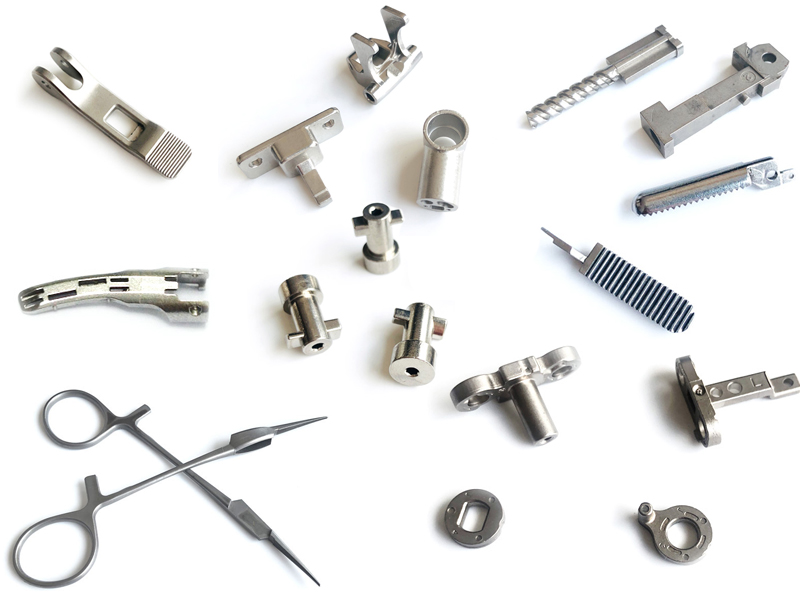

Medical Devices MIM Instrument Biopsy Forceps Tip Parts

- Product Details

- Company Profile

- Packaging&Shipping

- Ordering Steps

Medical Industry looks for superior physical properties, flexibility in selection of materials, corrosion resistance properties & reliability. Innovation in product design combined with artificial intelligence plays a vital role in today’s medical & surgical applications. Our offerings include high performance materials (e.g. SS316L, 17-4PH, SS420, SS304), stringent quality control, repeatability in dimensions, maintaining tight tolerances, ensuring product with superior corrosion resistance properties, extensive support in design & engineering, proto-typing activities in product development, support in multiple stage of product modifications, performance testing & supply of fully finished components. Our dedicated team with more than 15 years of experience & expertise in MIM technology are ready to support you in all critical requirement. We also provide solutions in over-molding & micro-molding.

metal injection molding medical Surgery Forceps components

Brand name | OEM & ODM |

Product type | Adjustable hinge mim part |

Product Model | MIM702 |

Material | Stainless steel 316L 304 17-4PH peptide Fe2Ni Fe4Ni Fe20Ni |

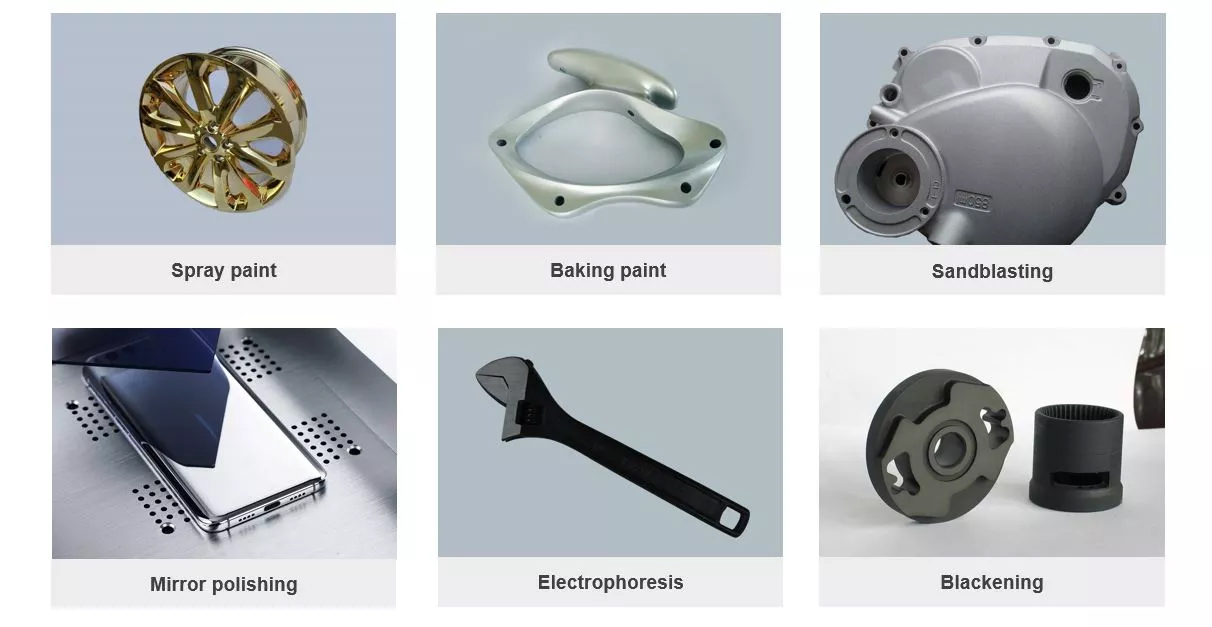

Post-Sintering | Polishing,Wire-drawing,Sandblasting,Plating,Coated,etc. |

Size | Custom |

Tolerance | 10mm±(0.02-0.04)mm |

Weight | 10g |

Forming Method | Powder Injection Molding |

Sintering method | Solid phase sintering |

Sintering environment | Vacuum |

Mold material | Stainless steel |

Application | Security industry |

Shape | Custom |

OEM | Accept |

QC system | 100% inspection before shipment |

Payment terms | T/T at sight, Paypal, Western Union,etc. |

Lead time | 7-15 working days |

Supply capability | 500000 Piece Per Month |

Packaging | PP bag / Anti-static film / anti-static plastic disc |

MIM Metal Product Application

What's the MIM technology and its advantages and features.

it’s suit to do mass production with complicated shapes;

1, MIM is an advanced metal forming technology that use injection molding machine to manufacturing precision and complex metal parts, which combines the advantage of PM and plastic injection molding.

it can use all kind of metal material(such as stainless steel, iron, ceramic and titanium, etc)

its relative density can achieve more than 98%

its finished products is close to final products, reducing the post-treatment cost, and then save production cost

compared with tranditional CNC and precision casting process, the structure are more even and preformance is much better

compared with PM(Powder Metallurgy), MIM can produce more complex shape and better preformance metal products.

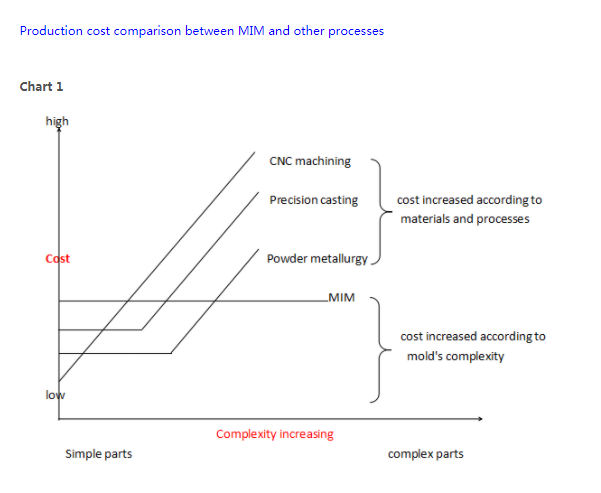

Production cost comparision between MIM and other processes

Cost Effective Design Flexibility/ Material Variety and Integrity

Powder metallurgy can ensure the accuracy and uniformity of the material composition ratio. Suitable for producing products of the same shape and large quantities, low production cost.

Medical Device Metal Components Manufacture Compare with other process

| Parameter | MIM | CONVENTIONAL PM | MACHINING | INVESTMENT CASTING |

| Density | 98% | 88% | 100% | 98% |

| Tensile Strength | High | Low | High | High |

| Elongation | High | Low | High | High |

| Hardness | High | Low | High | High |

| Min. Wall Thickness | 0.5 mm | 1 mm | 0.5 mm | 2 mm |

| Complexity | High | Low | High | Medium |

| Surface Finish | High | Medium | High | Medium |

| Production Volumes | High | High | Low | Medium |

| Range of Materials | High | High | High | Medium-High |

| Cost | Medium | Low | High | Medium |

Service:

1, 100% inspection before shipment.

2, Satisfied packing, carton, wooden case, pallet,or according to your requirement.

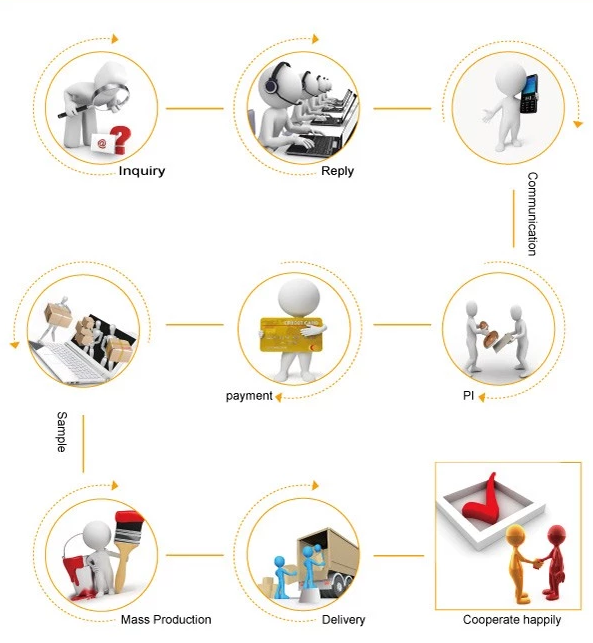

3, Samples are within 35-40 days after the receipt of the deposit. production will be finished about 25-30days after samples confirma

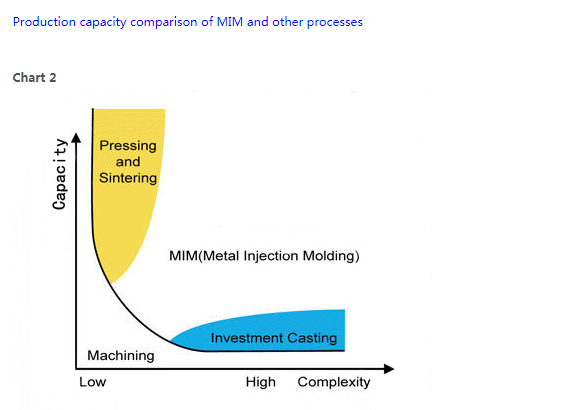

Production Capacity comparision of MIM and other process

Most difficult metals and compounds, pseudo alloys, porous materials can only be manufactured by powder metallurgy

Medical Device Metal Parts MIM Material

As a professional mim manufacturer in China, we are capable of working with various kinds of metals, including, iron-based (nickel-based alloys), titanium, tungsten alloys, cemented carbide, low-alloy steel, tool steel, magnetic materials and other medical-grade sheet metal alloys. We can also find specialty metals according to your custom requirements.

You can trust Harber for your complex small metal medical part needs. We have profound experience and history in mim industry, allowing us to develop top-notch mim products and finishing services. Our company offers high-volume and mass production for a number of precision manufacturers.

Harber is your one-stop solution for high-end product medical and pharmaceutical equipment. Our professional team can produce an extensive variety of metal parts for medical devices.