Contact Us

+86 13480709275

Block 11,Shunchang Industrial Park, Xiaobian Second Industrial Zone, Chang'an Town, Dongguan City, China

How Can We Help?

If You Need Any Helps Please Feel Free To

Powder Metallurgy Sintered Metal Shock Absorber Parts

- Product Details

- Company Profile

- Packaging&Shipping

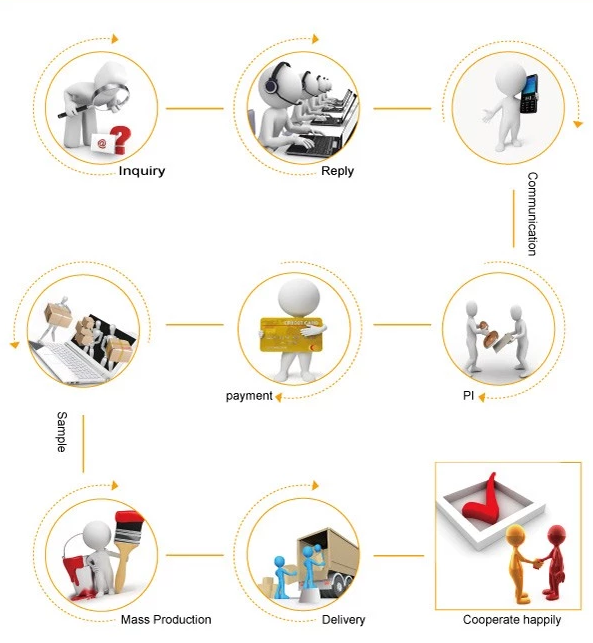

- Ordering Steps

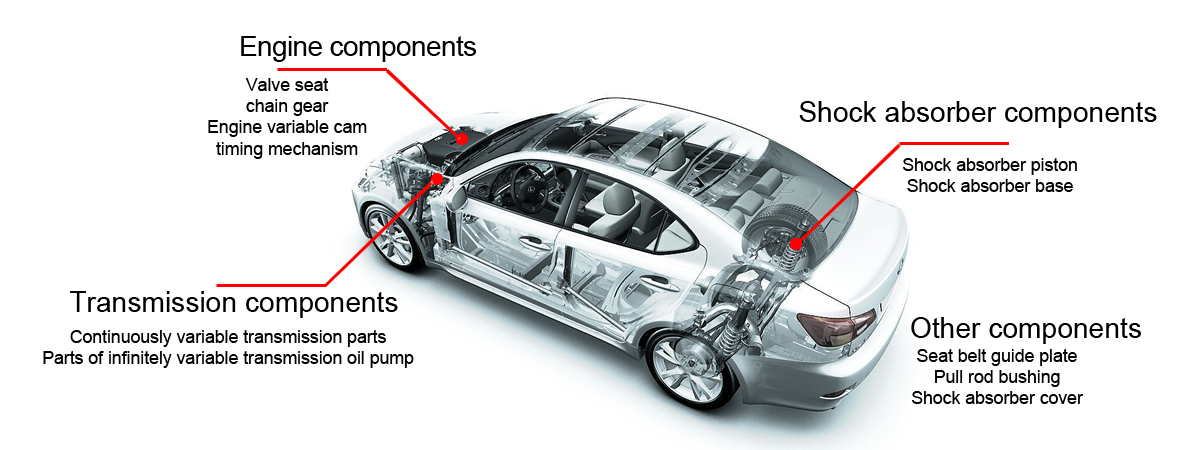

Powder metallurgy (sintered metal) products are used as components in various applications. A typical application is the automotive industry. Many powder metallurgy and sintered metal products are used in automobiles, such as engine parts, shock absorber parts, transmission parts, power steering parts, chassis parts, compressor parts, electric window parts, door parts, exhaust-related parts, etc. Additionally, they are used in other industries including engineering machinery, transportation machinery, agricultural machinery, textile machinery, embroidery machinery, medical machinery, office machinery, gas stations, hairdressing equipment, motors, appliances, tools, furniture, and all other fields.

Powdered Metal Precision Car Parts automotive shock absorber parts

Important components in the production of automotive shock absorber parts include the shock absorber piston and the shock absorber base. By developing and manufacturing pistons and bases with specialized materials and high-precision seating surfaces, as well as using low-friction resin-packed pistons, the stability of the damping force of the shock absorber is ensured, contributing to improved driving stability and passenger comfort.

Brand name | OEM & ODM |

Product type | Adjustable hinge mim part |

Product Model | MIM702 |

Material | Stainless steel 316L 304 17-4PH peptide Fe2Ni Fe4Ni Fe20Ni |

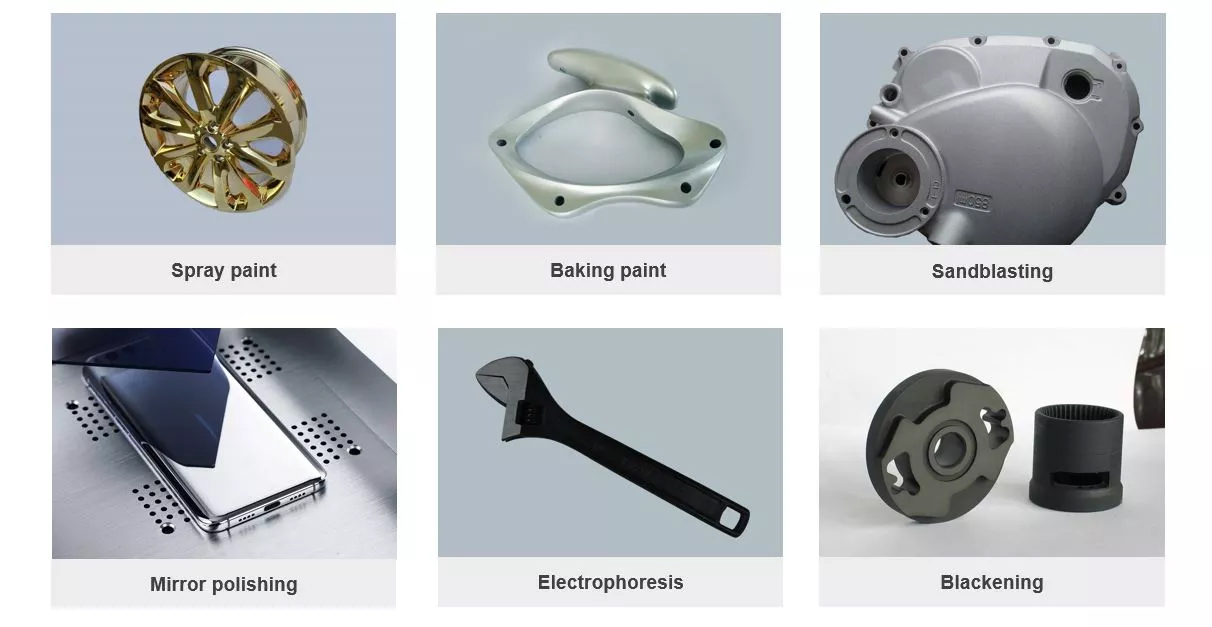

Post-Sintering | Polishing,Wire-drawing,Sandblasting,Plating,Coated,etc. |

Size | Custom |

Tolerance | 10mm±(0.02-0.04)mm |

Weight | 10g |

Forming Method | Powder Injection Molding |

Sintering method | Solid phase sintering |

Sintering environment | Vacuum |

Mold material | Stainless steel |

Application | Security industry |

Shape | Custom |

OEM | Accept |

QC system | 100% inspection before shipment |

Payment terms | T/T at sight, Paypal, Western Union,etc. |

Lead time | 7-15 working days |

Supply capability | 500000 Piece Per Month |

Packaging | PP bag / Anti-static film / anti-static plastic disc |

MIM is widely used in the automotive industry

Ignition control lock parts, turbocharger rotors, valve guide parts, automotive brake parts, automotive sunshade parts, clutch inner ring, fork bushing, distributor bushing, automotive conduit, etc.

What's the MIM technology and its advantages and features.

MIM is an advanced metal forming technology that use injection molding machine to manufacturing precision and complex metal parts, which combines the advantage of PM and plastic injection molding.

It's suit to do mass production with complicated shapes, create metal parts with complex geometries; MIM technology can accurately produce components features such as internal and external threads, undercuts, teeth (e.g., gear teeth), slots, holes, fins, markings, and engravings.

MIM process imposes few restrictions on the part design. It gives freedom to manufacture a variety of shapes, can fabricate multi-component parts as a single piece

Wide selection of metal materials for MIM, It can use all kind of metal material(such as stainless steel, carbon steel, copper alloys, nickel alloys, tungsten alloys, cobalt alloys, iron, carbide, ceramic and titanium, etc)

Its relative density can achieve more than 98%, MIM parts are produced with high density, resulting in excellent mechanical properties, including strength and hardness. This makes MIM a great solution for components that need to withstand high stress and wear.

Its finished products is close to final products, less material wastes and scrap than a machining process, which is important for expensive materials such as refractory materials, titanium alloys, superalloys, and specialty metals. reducing the post-treatment cost, and then save production cost.

Compared with tranditional CNC and precision casting process, the structure are more even and preformance is much better, Consistent part quality, Consistent part density & strength

Compared with PM(Powder Metallurgy), MIM can produce more complex shape and better preformance metal products.

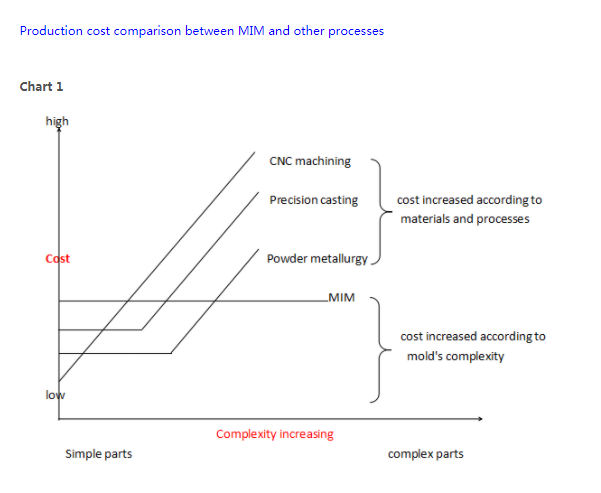

Production cost comparision between MIM and other processes

Cost Effective Design Flexibility/ Material Variety and Integrity

Powder metallurgy can ensure the accuracy and uniformity of the material composition ratio. Suitable for producing products of the same shape and large quantities, low production cost.

Auto Parts Manufacture Compare with other process

| Parameter | MIM | CONVENTIONAL PM | MACHINING | INVESTMENT CASTING |

| Density | 98% | 88% | 100% | 98% |

| Tensile Strength | High | Low | High | High |

| Elongation | High | Low | High | High |

| Hardness | High | Low | High | High |

| Min. Wall Thickness | 0.5 mm | 1 mm | 0.5 mm | 2 mm |

| Complexity | High | Low | High | Medium |

| Surface Finish | High | Medium | High | Medium |

| Production Volumes | High | High | Low | Medium |

| Range of Materials | High | High | High | Medium-High |

| Cost | Medium | Low | High | Medium |

Service:

1, 100% inspection before shipment.

2, Satisfied packing, carton, wooden case, pallet,or according to your requirement.

3, Samples are within 35-40 days after the receipt of the deposit. production will be finished about 25-30days after samples confirma

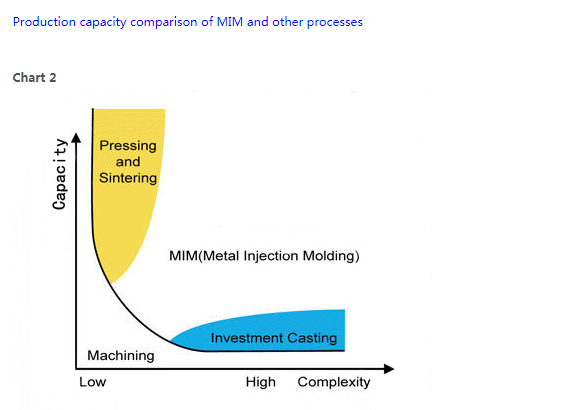

Production Capacity comparision of MIM and other process

Most difficult metals and compounds, pseudo alloys, porous materials can only be manufactured by powder metallurgy

Auto Parts MIM Material

| Material | Composition |

| Low alloy steel | Fe-2Ni, Fe-8Ni |

| Stainless steel | 316L, 17-4-PH |

| Tool steel | 42CrMo4, M2, Skd-11, C45 |

| Carbide | WC-Co(6%) |

| Ceramics | Al203, ZrO2, SiO2 |

| Tungsten alloy | W-Ni-Fe, W-Ni-Cu, W-Cu |

Powder Metallurgy Ultra Power Auto Parts

Powder metallurgy products have advantages in energy saving, material saving, environmental protection, economy, high efficiency and so on, which are gradually recognized by various industries and widely used; especially the application and development of automotive powder metallurgy products, which pushes the powder metallurgy industry into the fast lane of development.

Powder metallurgy parts used in automobiles are products with very high scientific and technological content, which can reduce the weight of automobiles and lower manufacturing costs, and have the effect of optimizing the production process of automobile industry products and improving the competitiveness of the automobile industry, and at present, the powder metallurgy parts used in automobiles in the world are more than 400 kinds of powder metallurgy parts.

Your Partner for Automotive Metal Shaped Solutions

As a global market leader for metal injection molding mim components, we deliver customized high-precision metal shaped solutions and engineering support to enable industrial and automotive parts innovations. MIM auto parts are near fully dense, which gives excellent mechanical, magnetic, corrosion and hermetic sealing properties, and allows secondary operations like plating, heat treating, and machining to be easily performed.