Contact Us

+86 13480709275

Block 11,Shunchang Industrial Park, Xiaobian Second Industrial Zone, Chang'an Town, Dongguan City, China

How Can We Help?

If You Need Any Helps Please Feel Free To

Low Cost SS MIM Stainless Steel Parts

Harber Industrial Ltd is a leading manufacturer of Metal Injection Molding Products, Powder Metallurgy Parts and precision metal parts that other conventional processing produce.We have developed more than 2000 different mim metal components for these applications alone. Our offering includes variety of materials with different properties such as high strength, wear resistance, corrosion resistance etc. In recent times with increase in automation across the industry, usage of MIM components becoming more popular & familiar. Our experience in serving this segment for a long time gives us immense advantage to understand specific requirement, and provide cost-effective quality solutions accordingly.

- Product Details

- Company Profile

- Packaging&Shipping

- Ordering Steps

Stainless steel is a suitable material for various mim manufacturer projects, because it has great machinability and uniformity. It also has good workability and weldability for your specific machining needs, as well as high ductility and formability to meet the criteria of any project.

Stainless steel is one of the most preferred industrial alloys for metal injection mold projects, because of its favorable physical properties. The metal has a very high tensile strength, and can withstand corrosion and wear, which improves product durability and part longevity.

Custom Made Sintered Stainless Steel Powder Materials

| GRADE | TYPE | DESCRIPTION | APPLICATIONS |

| SS-303 N1 SS-304 N1 SS-316 N1 (6.5-6.8g/cc) | Austenitic | ‘Low-temperature’ sintered in a nitrogen atmosphere to provide a nitrogen-induced wear surface, good strength, and lower ductility | Pump components, threaded marine components, non-magnetic housings |

| SS-303 N2 SS-304 N2 SS-316 N2 (6.6-7.0g/cc) | Austenitic | ‘High-temperature’ sintered in a nitrogen atmosphere to provide a nitrogen induced wear surface, high strength, and improved ductility | Pump components, threaded marine components, non-magnetic housings, all requiring improved physical properties |

| SS-303L SS-304L SS-316L (6.8-7.1g/cc) | Austenitic | ‘High-temperature’ sintered in either partial vacuum or a hydrogen atmosphere to improve the ductility and corrosion resistance | Food service equipment, pump components, marine components, and non-magnetic housings |

| Ultimet 16 (7.2g/cc to 7.5g/cc) | Duplex | ‘High-temperature’ sintered in a hydrogen atmosphere significantly improving the ductility and corrosion resistance | Hardware, locks, fittings, flanges, pump components, and housings |

| SS-409L SS-409CB SS-410L SS-430L SS-434L 6.9 to 7.3g/cc | Ferritic | ‘High-temperature’ sintered in a hydrogen atmosphere, densities above 7.2 g/cc optimize the welding characteristics and magnetic properties | Magnetic probes and sensors, armatures, and pole pieces requiring protection from atmospheric corrosion and general oxidation |

| SS-410N2 SS-430N2 SS-434N2 6.9 to 7.3g/cc | Ferritic | ‘High-temperature’ sintered in a nitrogen atmosphere, slightly higher strength than ‘L’ series with reduced corrosion resistance and magnetic response | Magnetic probes and sensors, armatures, and pole pieces requiring protection from atmospheric corrosion and general oxidation |

| SS-410HT SS-420HT SS-440HT 6.6 to 7.2g/cc | Martensitic | ‘High-temperature’ sintered in a hydrogen atmosphere increasing hardness and strength over other stainless steels | Wear plates, fuel injection nozzles, and cutting instruments |

Harber Metal Equipment advantages:

Mixing machine, Injection molding machines, Degreasing furnaces, Vacuum sintering furnace; Automatic pressing machine, Repressing machine, CNC machining equipment, finishing machining machine, polishing machine, Automatic oil punching machine and so on...

Harber Metal Testing equipment:

Projector, Salt spray test machine, Partial pendulum instrument, electronic balance, electronic gravity apparatus, universal tester, Rockwell hardness tester, Density tester, gauge block, dial indicator, micrometer, Vernier.

What's the MIM technology and its advantages and features.

Simple to Complex Designs

A multitude of design capabilities as there is no extra cost for unlimited features or markings, precision complex net-shape components from a variety of compositions

Metal Variety

Suitable for almost any type of metal, it can use all kind of metal material(such as stainless steel, iron, ceramic and titanium, etc)

Low Tolerances

Metal injection molding can maintain low overall dimensional and locational tolerances

Quick Prototyping

Quick turnaround on short runs. Compound tooling can combine more than one prototype with the same material

Low Cost Modifiable Tooling

Produced quickly and low-cost revisions, MIM injection molding can produce precise part geometry without cutting and secondary processing. It can produce high-density and highly complex structural parts and reduce costs for the whole production. its finished products is close to final products, reducing the post-treatment cost, and then save production cost

Intact Metal Properties

The density of structural parts varies greatly. The friction between PM powder and tools will make the parts uneven. The MIM injection molded parts are uniform in all directions, and the relative density can reach 95% - 99%. The sintering temperature of MIM is much higher than that of PM, the strength, toughness and wear resistance of MIM injection molding are significantly higher, and the utilization of raw materials is high.

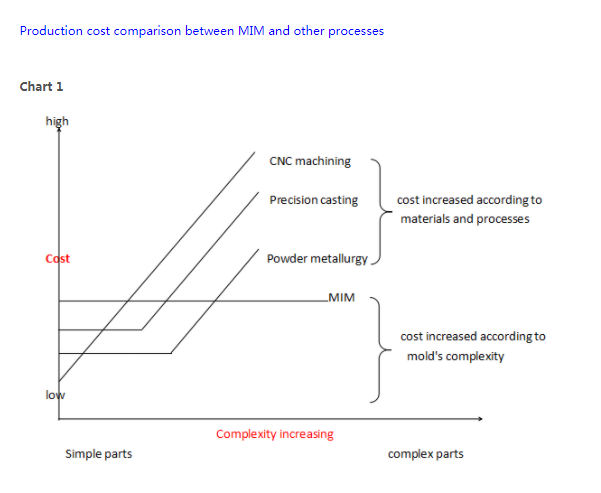

compared with tranditional CNC and precision casting process, the structure are more even and preformance is much better

compared with PM(Powder Metallurgy), MIM can produce more complex shape and better preformance metal products.

Environmentally Responsible

The metal injection molding solution (raw materials) is recyclable, safe to use, and can be reused for future metal molding

MIM Metal Product Application

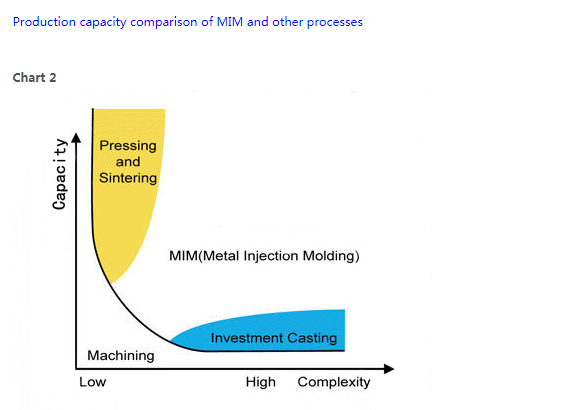

Production cost comparision between MIM and other processes

Cost Effective Design Flexibility/ Material Variety and Integrity

Powder metallurgy can ensure the accuracy and uniformity of the material composition ratio. Suitable for producing products of the same shape and large quantities, low production cost.

Compare with other process

| Parameter | MIM | CONVENTIONAL PM | MACHINING | INVESTMENT CASTING |

| Density | 98% | 88% | 100% | 98% |

| Tensile Strength | High | Low | High | High |

| Elongation | High | Low | High | High |

| Hardness | High | Low | High | High |

| Min. Wall Thickness | 0.5 mm | 1 mm | 0.5 mm | 2 mm |

| Complexity | High | Low | High | Medium |

| Surface Finish | High | Medium | High | Medium |

| Production Volumes | High | High | Low | Medium |

| Range of Materials | High | High | High | Medium-High |

| Cost | Medium | Low | High | Medium |

Service:

1, 100% inspection before shipment.

2, Satisfied packing, carton, wooden case, pallet,or according to your requirement.

3, Samples are within 35-40 days after the receipt of the deposit. production will be finished about 25-30days after samples confirma

Production Capacity comparision of MIM and other process

Most difficult metals and compounds, pseudo alloys, porous materials can only be manufactured by powder metallurgy