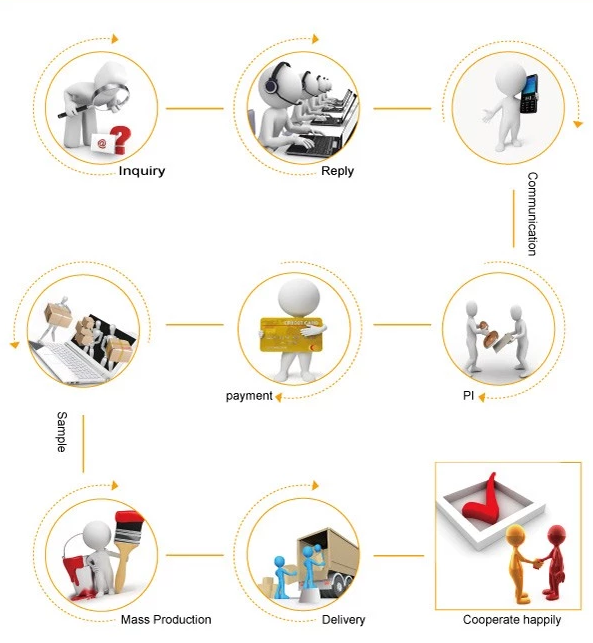

With over 10 years' experience in powder metallurgy, Harber provides high-end global customers with high-quality components and advanced one-stop solutions. Our zero-defect products covers in such businesses fields as Automotive, Medical application, Houshold, Consumer electronics, Hardware tools and Lock. Best raw materials, strict inspection control and cutting-edge know-how has made Harber a reliable and professional profile to our customers from all over the world. We are sure that Harber can meet any needs from them by using our expertise, credibility and technicality.

We have fully professional and high standard automated production line which contain:Powder metallurgy automated batching system, Advanced level automatic powder molding machine(60T-300T), Mesh belt sintering furnace, Steam treatment furnace, finishing machines, Powder metallurgy physical and chemical equipment, Robot manipulator,Fiber laser marking machine,Advanced testing equipment (universal testing machine, digital mapping instrument, etc.) . All these equipments support the high speed, the highest accuracy, to ensure product development and production.

Harber Metal has excellent talents in the field of powder metallurgy, mature powder metallurgy production technicians, and long-term cooperation with domestic top powder metallurgy research laboratories. It is a comprehensive high-tech enterprise integrating research, development, production and sales of powder metallurgy structural parts.

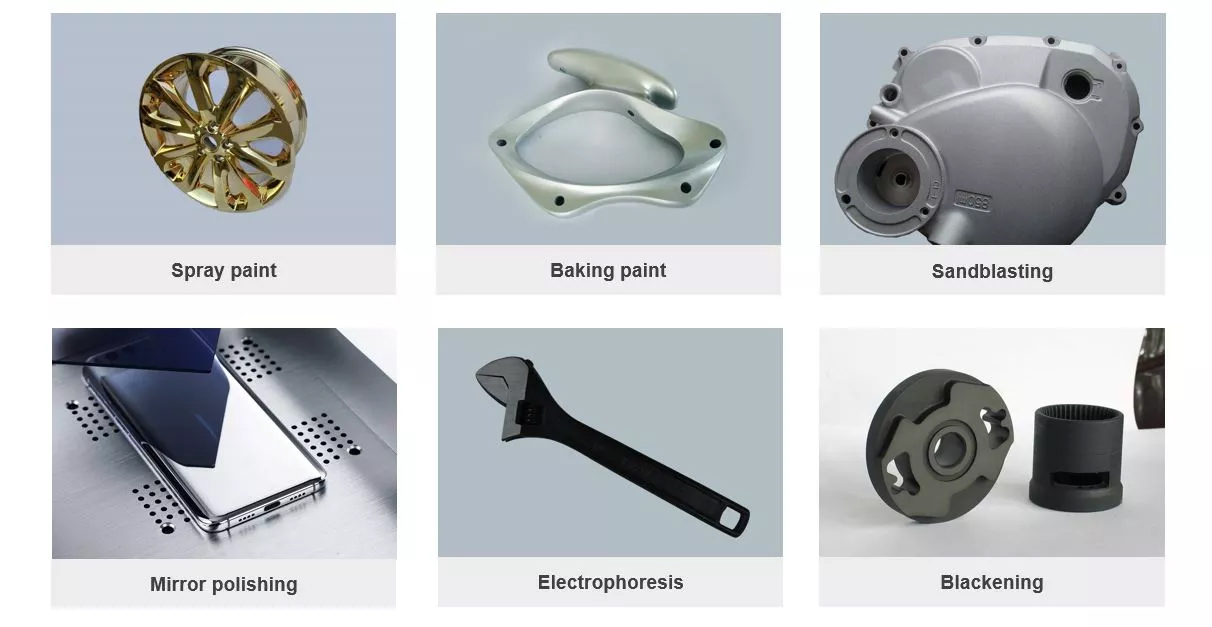

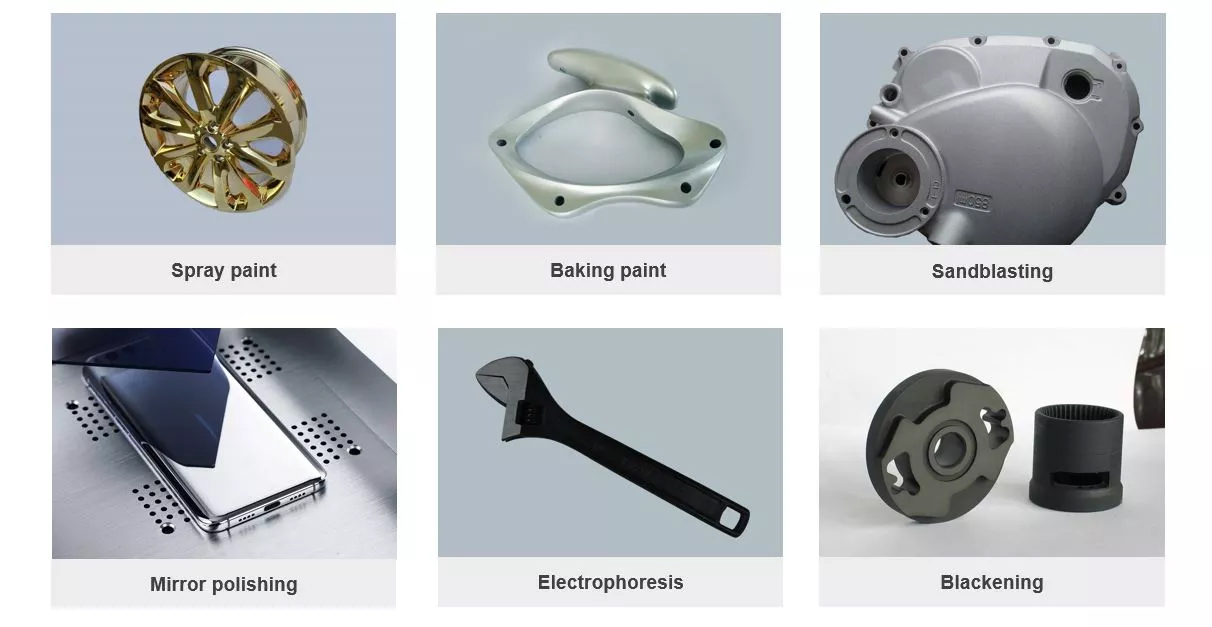

Surface Treatment

Harber can offer such surface finish (secondary process) as sandblasting, electric polishing, magnetic grinding, laser engraving, PVD, carburizing, Permeability nitrogen and annealing.