Contact Us

+86 13480709275

Block 11,Shunchang Industrial Park, Xiaobian Second Industrial Zone, Chang'an Town, Dongguan City, China

How Can We Help?

If You Need Any Helps Please Feel Free To

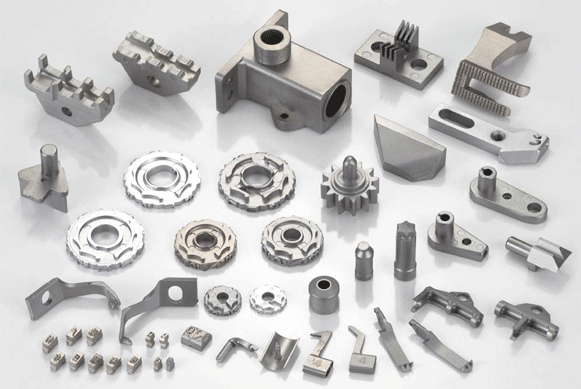

Machinery Structural Parts

Metal powder injection molding (MIM) can be used to produce a wide variety of parts, including decorative items, fashion accessories, industrial products, mechanical structures such as bearing housings, connecting rods, and camshafts, mobile phone accessories, lock components, mechanical parts, pneumatic and electric tool components, and grind cores.

Industrial equipment structural parts refer to the components of machinery, equipment, and systems that are responsible for providing structural support and stability. These parts include frames, brackets, mounts, fasteners, and other components that are critical to the overall function and performance of the equipment. They are typically manufactured to high precision, quality, and durability standards in order to withstand heavy loads and frequent physical and chemical effects.

Powder Metal

Powder Metal is a manufacturing process offered by Harber Group that is characterized by forming parts from a metal powder. The process starts with a mixture of blended iron, coppers, nickel, and other alloys, depending on the requirements from the application. The powder is transferred into the press thru gravity feed systems, next the powder metal is compacted in a tool to form the part, followed by a sintering operation in an oven to mechanical bond the metal together. Most powder metal parts are made from ferrous metals, specifically steel alloys.

Understanding the Benefits

The Powder Metal process can be used to create materials that cannot be created in normal ingot grades to achieve special properties by melting. Many times, net shape parts can be produced resulting in a finished part with little or no secondary processes. The tools, built from tool steel, are reusable so the powder metal process can produce economical part prices for higher volume programs. Typical volumes start at 25,000/year and go higher from there. Casting parts and forging have their advantages for more complex geometry, but the costs are often higher with these processes.

Secondary Operations

We offer various machining, plating and finishing operations in-house to provide a finished part.

Our alloys

non-ferrous metals

Steel alloys

Stainless Steels (300 and 400 series)

Specialty blend alloys

Additional information on these alloys and standard tolerances here.

Contact us today to discuss your Powder Metal projects. We proudly serve clients from all over the world.

Reach Out to Discuss Your MIM Project

Do you need a quote for your high-precision complex mim Components? Contact us now by phone, email, or through our contact form.