Contact Us

+86 13480709275

Block 11,Shunchang Industrial Park, Xiaobian Second Industrial Zone, Chang'an Town, Dongguan City, China

How Can We Help?

If You Need Any Helps Please Feel Free To

MIM Sintered Metal Electronic Lock Parts

Harber is a leading manufacturer of Metal Injection Molding Products, Powder Metallurgy Parts and precision metal parts that other conventional processing produce.We have developed more than 2000 different mim metal components for these applications alone.

- Product Details

- Company Profile

- Packaging&Shipping

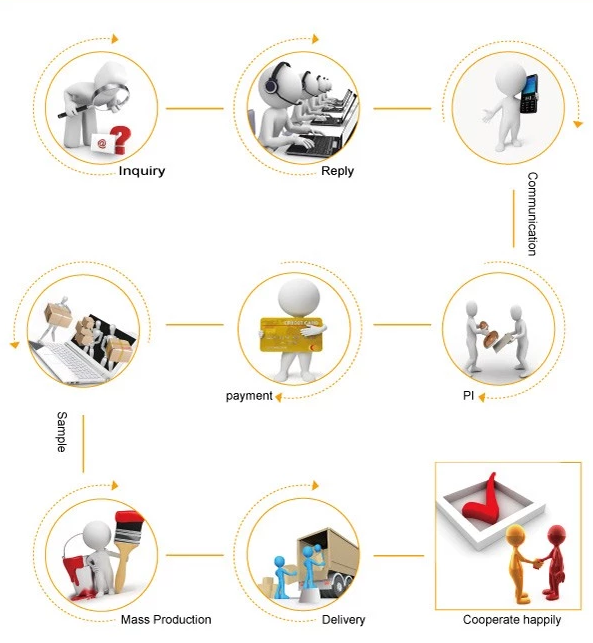

- Ordering Steps

Powder Metallurgy MIM Sintered Metal Electronic Lock Parts

In the door lock system, there are three most crucial MIM lock components whose relative positions determine the opening and closing of the door. In order to enhance the anti-theft function of the door lock, these functional components are made of high-strength alloy steel materials. To meet the requirements, our company specially uses high-strength low-alloy steel materials with a hardness of up to 50HRC, which can be easily surface treated.

The Powder Metal process can be used to create materials that cannot be created in normal ingot grades to achieve special properties by melting. Many times, net shape parts can be produced resulting in a finished part with little or no secondary processes. The tools, built from tool steel, are reusable so the powder metal process can produce economical part prices for higher volume programs.

Metal Injection Molding Electronic Sintered Door Lock Part

Brand name | OEM & ODM |

Product type | Sintered Metal Parts of a Electronic Locks |

Product Model | MIM702 |

Material | Stainless steel 316L 304 17-4PH peptide Fe2Ni Fe4Ni Fe20Ni |

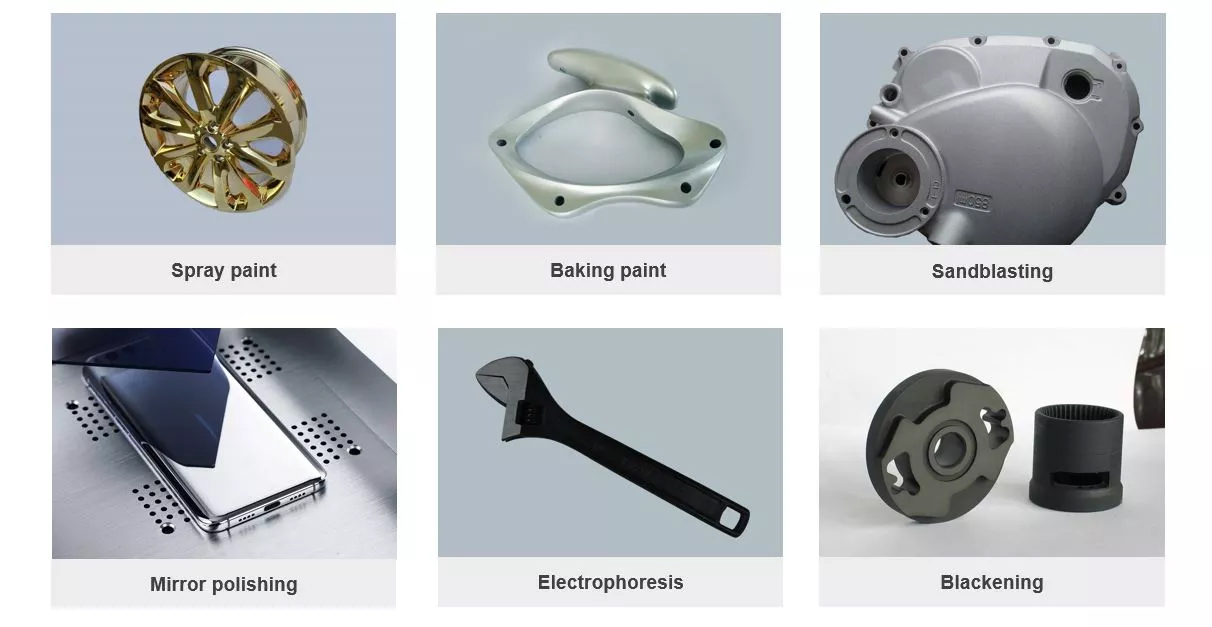

Post-Sintering | Polishing,Wire-drawing,Sandblasting,Plating,Coated,etc. |

Size | Custom |

Tolerance | 10mm±(0.02-0.04)mm |

Weight | 10g |

Forming Method | Powder Injection Molding |

Sintering method | Solid phase sintering |

Sintering environment | Vacuum |

Mold material | Stainless steel |

Application | Security industry |

Shape | Custom |

OEM | Accept |

QC system | 100% inspection before shipment |

Payment terms | T/T at sight, Paypal, Western Union,etc. |

Lead time | 7-15 working days |

Supply capability | 500000 Piece Per Month |

Packaging | PP bag / Anti-static film / anti-static plastic disc |

MIM Equipment advantages:

Mixing machine, Injection molding machines, Degreasing furnaces, Vacuum sintering furnace; Automatic pressing machine, Repressing machine, NC machining equipment, finishing machining machine, polishing machine, Automatic oil punching machine and so on...

Testing equipment:

Projector,Salt spray test machine,Partial pendulum instrument,electronic balance,electronic gravity apparatus,universal tester,Rockwell hardness tester,Density tester,gauge block,dial indicator,micrometer,Vernier.

What's the MIM technology and its advantages and features.

MIM is an advanced metal forming technology that use injection molding machine to manufacturing precision and complex metal parts, which combines the advantage of PM and plastic injection molding.

It's suit to do mass production with complicated shapes, create metal parts with complex geometries; MIM technology can accurately produce components features such as internal and external threads, undercuts, teeth (e.g., gear teeth), slots, holes, fins, markings, and engravings.

MIM process imposes few restrictions on the part design. It gives freedom to manufacture a variety of shapes, can fabricate multi-component parts as a single piece

Wide selection of metal materials for MIM, It can use all kind of metal material(such as stainless steel, carbon steel, copper alloys, nickel alloys, tungsten alloys, cobalt alloys, iron, carbide, ceramic and titanium, etc)

Its relative density can achieve more than 98%, MIM parts are produced with high density, resulting in excellent mechanical properties, including strength and hardness. This makes MIM a great solution for components that need to withstand high stress and wear.

Its finished products is close to final products, less material wastes and scrap than a machining process, which is important for expensive materials such as refractory materials, titanium alloys, superalloys, and specialty metals. reducing the post-treatment cost, and then save production cost.

Compared with tranditional CNC and precision casting process, the structure are more even and preformance is much better, Consistent part quality, Consistent part density & strength

Compared with PM(Powder Metallurgy), MIM can produce more complex shape and better preformance metal products.

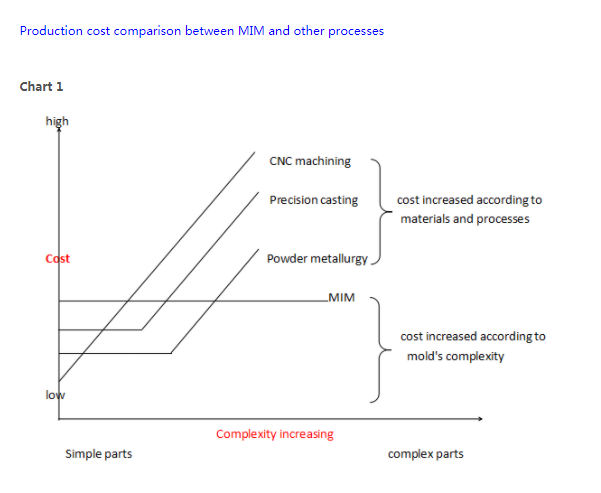

Production cost comparision between MIM and other processes

Cost Effective Design Flexibility/ Material Variety and Integrity

Powder metallurgy can ensure the accuracy and uniformity of the material composition ratio. Suitable for producing products of the same shape and large quantities, low production cost.

Compare with other process

| Parameter | MIM | CONVENTIONAL PM | MACHINING | INVESTMENT CASTING |

| Density | 98% | 88% | 100% | 98% |

| Tensile Strength | High | Low | High | High |

| Elongation | High | Low | High | High |

| Hardness | High | Low | High | High |

| Min. Wall Thickness | 0.5 mm | 1 mm | 0.5 mm | 2 mm |

| Complexity | High | Low | High | Medium |

| Surface Finish | High | Medium | High | Medium |

| Production Volumes | High | High | Low | Medium |

| Range of Materials | High | High | High | Medium-High |

| Cost | Medium | Low | High | Medium |

Service:

1, 100% inspection before shipment.

2, Satisfied packing, carton, wooden case, pallet,or according to your requirement.

3, Samples are within 35-40 days after the receipt of the deposit. production will be finished about 25-30days after samples confirma

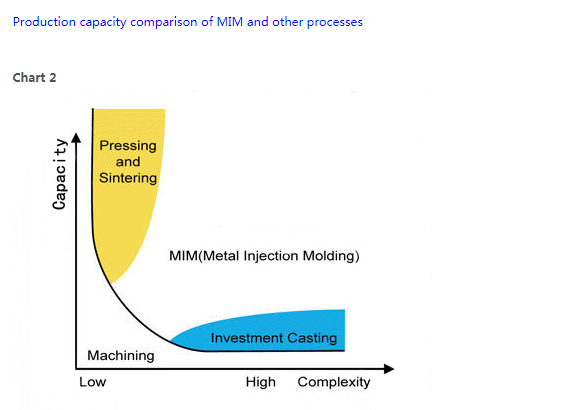

Production Capacity comparision of MIM and other process

Most difficult metals and compounds, pseudo alloys, porous materials can only be manufactured by powder metallurgy

MIM material

| Material | Composition |

| Low alloy steel | Fe-2Ni, Fe-8Ni |

| Stainless steel | 316L, 17-4-PH |

| Tool steel | 42CrMo4, M2, Skd-11, C45 |

| Carbide | WC-Co(6%) |

| Ceramics | Al203, ZrO2, SiO2 |

| Tungsten alloy | W-Ni-Fe, W-Ni-Cu, W-Cu |

All kinds of precision metal injection molding(MIM) and powder molding(PM) hardwares; sinter gears(bevel gear,pinion gear,worm gear and helical gear),complex-shape metal parts(like hair clipper blade, nail clipper parts, scalpel, lock bolt), sprocket, pulley and stainless steel precision die-casting parts,etc.